Selected projects plant design / construction and operation at a glance

2019 to date...

- Operation of the DFT plant at the Reichstädt site.

- Production of K products, including K pellets as animal bedding,

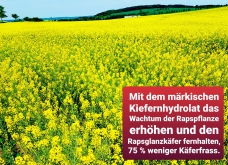

- Production of K-Hydrolate for agriculture as a plant strengthening agent,

- Production of K-Hydrolat as cleaning and disinfecting agent,

- Production of pine essential oil.

2012/2014

- Reengineering VZR Reichstädt Process Center Ltd.

- Planning of the change of use of a plant for the production of wood pellets.

2011/2012

- Planning and construction of a fuel gas cleaning system for the IFF Fraunhofer Institute in Magdeburg.

- WSV & WSK with a biomass-fuel capacity of 1 MW.

2011 - today

- DEUSA International GmbH

Planning and construction preparation of the DMSV-plant (DEUSA-multi-stage-gasification-plant) for plastics

- LEHMANN Maschinenbau GmbH

Commissioning LMSV-plant (Air-multi-stage-gasifier)

2010/2011

- Fraunhofer Gesellschaft, IFF (Institute for Factory operation and automation)

Planning, construction and commissioning of an fuel gas cleaning system with WSK (fluidized bed cooling) for 600 Nm³/h flue gas from wood gasification

2008/2009

- RWTH Aachen

Realization of the flue gas recirculation for OXYCOAL-AC process

- DEUSA International GmbH

Test procedure for gas conditioning of a gasification plant

- Amand Umwelttechnik Lockwitz GmbH & Co.KG

Test procedure for additional flue gas cleaning at power plant of Amand Umwelttechnik Lockwitz GmbH & Co.KG

2007/2008

- LEHMANN Maschinenbau GmbH

CombiCompact-gasification plant in modular construction

- Technical University Dresden

Manufacturing of a fluidized bed cooler with tar binding fluidization medium

- POW AG

Construction preparation CombiPower plant Naundorf

2005/2006

- VER Verfahrensingenieure GmbH/ WV Wärmeversorgung (heat supply) Großenhain GmbH

Basic Engineering for nature wood gasification and/or plantation wood with 3,5 t/h

- VER Verfahrensingenieure GmbH/ Company from Thüringia

Planning for a biomass gasification plant by the LQV-process with a fuel power of 2000 kW

2001

- SVZ Schwarze Pumpe GmbH

Delivery, construction management and commissioning of a drying plant for 120,000 t/a tar-sewage-sludge-mixture (DFT - vapor fluid dryer)

2000

- Technical University Dresden

Delivery of a 75 kW testing gasifier

- ZEUS Energie- und Umweltsysteme Zwönitz GmbH

Planning, delivery and commissioning of a flue gas cleaning plant for a wood chips firing low-power < 1MW thermal

- VER GmbH / VZR Reichstädt

Extension of DFT®-plant in Reichstädt with planning and construction of a biological exhaust cleaning system

1999

- SVZ Schwarze Pumpe GmbH

Order to supply, construction management and commissioning of a drying plant for 120.000 t/a tar-sewage-sludge-mixture

1998

- VER GmbH

Production operation at the plant for paint sludge drying in Reichstädt (Sa.)

1996 - 1998

- VER GmbH

Construction of the plant for color and paint sludge drying in Reichstädt (Sa.) by the DFT®-process with evaporation power of 1000 kg/h

1994 - 1996

- VER GmbH

Development and approval planning for the color and paint sluge drying plant in Reichstädt (Sa.)

1995

- VER GmbH

Testing operation at the LQV® (Air cross-flow gasification) plant in Freital (pilot plant)

1993 – 1995

- VER GmbH

Development, planning and construction of the LQV® (Air cross-flow gasification) plant in Freital (pilot plant)